Building materials

-

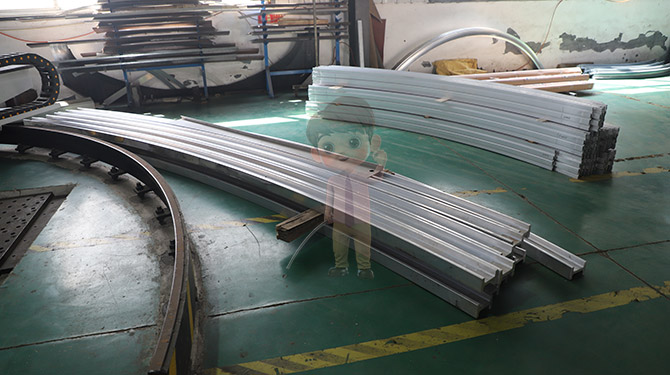

Aluminum-clad wood profile drawing and bending

-

Steel stretching and bending

-

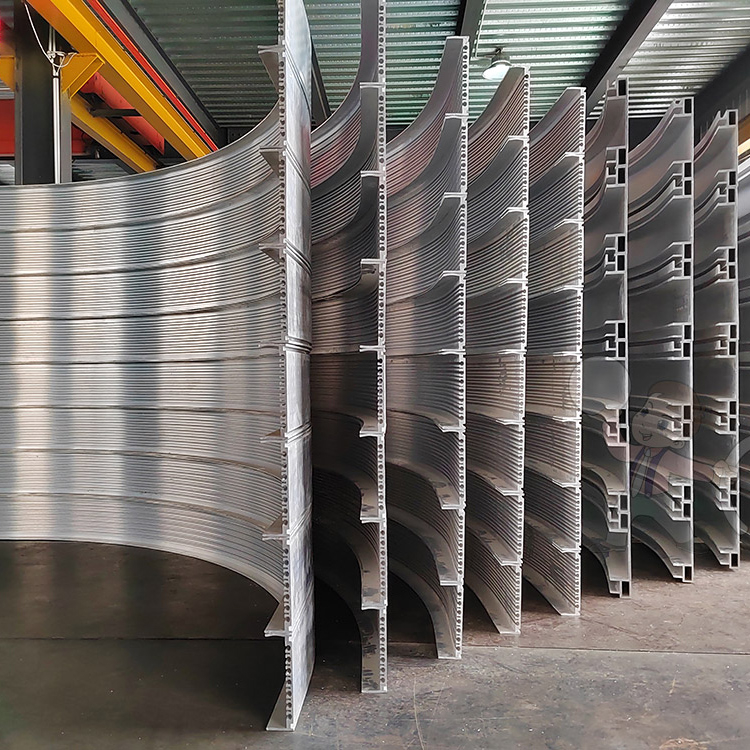

Revolving door profile stretching bend

-

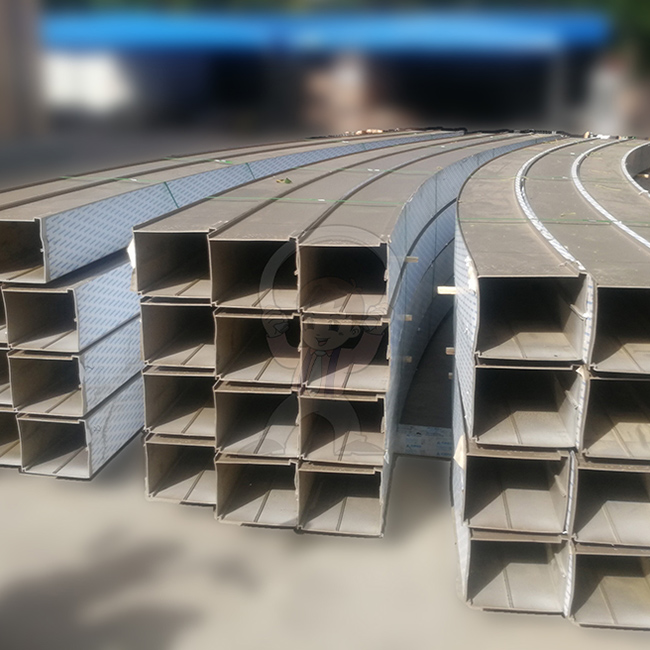

Shuttle-type louver grating

-

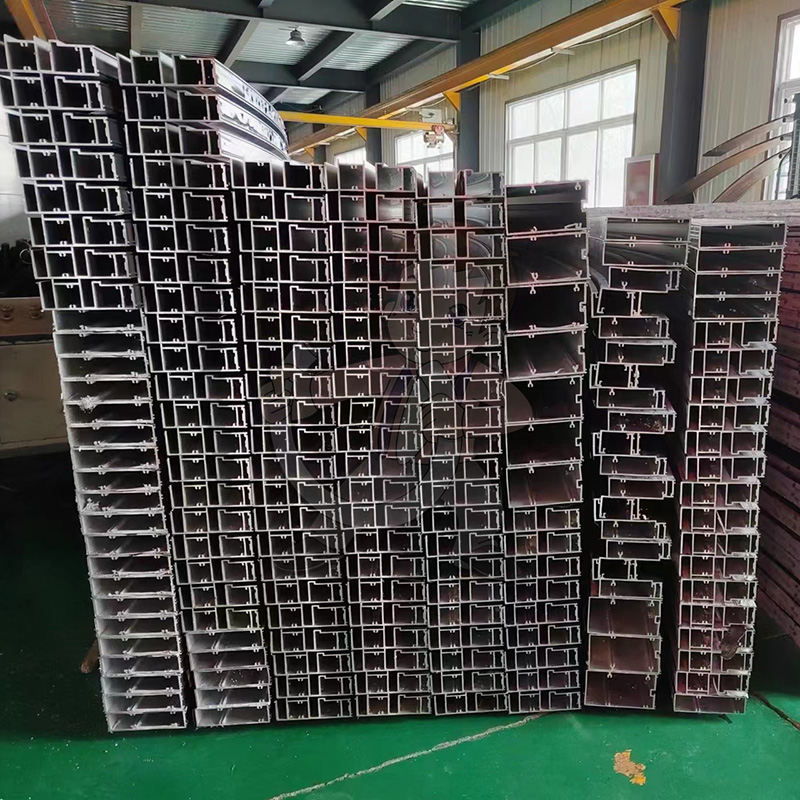

Special-shaped aluminum profile stretching and bending processing

-

Broken bridge aluminum profile tensile bending

-

Unit curtain wall profile stretching bending

-

Blade stretching and bending processing

-

Aluminum alloy decorative material stretching bending processing

English

English Chinese

Chinese Japan

Japan German

German