Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

Plastic steel, also known as uPVC or unplasticized polyvinyl chloride profiles, has become a popular material in modern construction, particularly for doors, windows, curtain walls, and other architectural elements. One of the key processes in utilizing plastic steel isbending, which allows the creation of custom shapes, curves, and complex structures while maintaining the material’s strength and durability. Achieving bothprecision and efficiency in plastic steel bending is critical for architects, engineers, and manufacturers to deliver high-quality results in a cost-effective manner. This article explores the key techniques for plastic steel bending and the benefits that come with precise and efficient processing.

Plastic steel bending involves shaping uPVC profiles into curves or angles without compromising structural integrity. Unlike metals, which can be hammered or pressed into shape, plastic steel requirescontrolled heating and forming to achieve the desired curvature. If handled improperly, the material can warp, crack, or lose its dimensional stability.

The bending process is widely applied in:

Architectural doors and windows: creating arched or curved frames for aesthetic and functional purposes.

Curtain walls and facades: achieving smooth, flowing lines in modern building designs.

Interior design elements: producing custom profiles for partitions, handrails, or decorative trim.

Achieving precision in plastic steel bending depends on several factors, including temperature control, bending radius, and tooling. The most commonly used techniques include:

1.Hot Air or Heat Gun Bending

Using a heat source such as a hot air gun, plastic steel profiles can be heated until pliable. This method allowsmanual or semi-automated bending of the material. Key considerations include:

Temperature control: uPVC softens around 160–180°C; overheating can cause surface burn or deformation.

Even heating: ensuring uniform heat distribution prevents warping or uneven curvature.

Bending jigs: using molds or forms helps maintain consistent shapes and radii.

This technique is especially suitable forsmall-scale projects or custom designs, where high flexibility is required.

2.Hot Water or Steam Bending

Immersing plastic steel profiles in hot water or exposing them to steam can also soften the material, making it bendable. Benefits of this method include:

Uniform softening: reduces the risk of cracks or surface stress.

Eco-friendliness: uses water or steam instead of electricity-intensive heating equipment.

Versatility: ideal for larger profiles or longer bending sections.

After bending, the profiles are cooled in a mold toretain the desired shape, ensuring precision and stability.

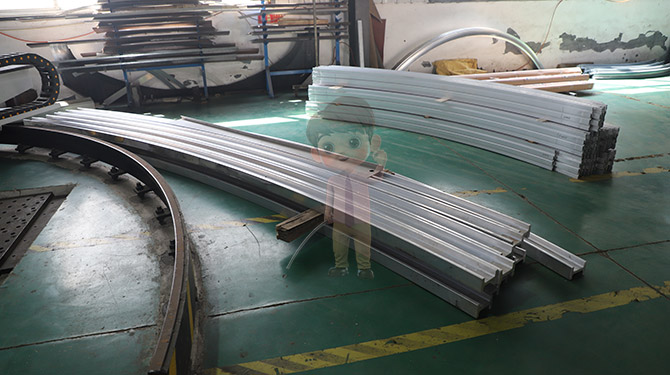

3.Machine-Assisted Bending

For industrial-scale production,automatic or semi-automatic bending machines provide the highest efficiency and repeatability. Features often include:

Programmable bending angles and radii: precise control over curvature.

Integrated heating systems: uniform and controlled softening of plastic steel.

High throughput: ideal for batch production of standard or custom curved profiles.

Machine-assisted bending reduces human error, ensures consistent quality, and is particularly effective forprojects with strict dimensional requirements, such as curtain walls and standardized door frames.

Proper plastic steel bending offers numerous advantages for both manufacturers and end-users:

1.Enhanced Structural Integrity

Precision bending ensures that the profiles maintain their strength and shape. Controlled heating prevents cracks, wrinkles, or stress marks, which can compromise the durability of windows, doors, or structural elements.

2.Aesthetic Flexibility

Modern architectural designs increasingly demand curved and flowing forms. Efficient bending techniques allow architects to achievecustom shapes and seamless curves, enhancing the visual appeal of buildings without sacrificing performance.

3.Time and Cost Savings

Efficient bending processes, especially machine-assisted methods, significantly reduce production time. By minimizing trial-and-error and manual adjustments, manufacturers canincrease throughput and lower labor costs while maintaining high-quality output.

4.Consistency Across Batches

For large-scale projects, consistency is critical. Accurate bending ensures that each profile matches the required specifications,facilitating installation and reducing the risk of mismatched components during assembly.

5.Sustainability and Reduced Waste

Precision bending minimizes material waste caused by errors or misaligned curves. This not only reduces production costs but also supports more sustainable construction practices.

Even with advanced techniques, several factors influence the success of plastic steel bending:

1.Profile Thickness and Shape: Thicker profiles require more careful heating and longer bending times. Complex cross-sections may need specialized molds.

2.Temperature and Heating Duration: Overheating or uneven heating can damage the profile, while insufficient heat may prevent proper bending.

3.Cooling and Mold Retention: Rapid cooling without proper support can lead to spring-back or deformation. Cooling in a mold ensures the curve holds accurately.

4.Skill Level and Equipment Quality: Experienced technicians and high-quality bending machines contribute significantly to efficiency and precision.

Plastic steel bending is a vital process in modern construction and industrial applications, allowing the creation of aesthetically pleasing, durable, and functional profiles. Achievingprecision and efficiency requires a combination of proper heating techniques, reliable molds or machinery, and skilled operators.

The benefits are clear: enhanced structural integrity, aesthetic flexibility, cost and time efficiency, batch consistency, and reduced material waste. As demand for curved and customized architectural elements grows, mastering plastic steel bending techniques will remain a key factor for manufacturers aiming to deliver high-quality, innovative solutions.

By investing in the right bending methods and understanding the critical factors that influence outcomes, construction professionals and manufacturers can fully leverage the potential of plastic steel, producing structures that are both beautiful and resilient.

26

2026-01

Number of visitors:1

HOT NEWS

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

-

Advanced Aluminum Profile Bending Techniques: Precision Solutions for Complex Curved Structures

2026-01-06

-

Selection and Maintenance Strategies for Aluminum Bending Equipment

2025-12-27

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST