Investing in precision hot bending not only enhances product quality but also ensures that complex designs can be realized safely and reliably, making it a critical capability for modern metal fabrica

In the days to come, Shendala Bending will continue to uphold the concept of "Unity, Synchronization, and Growth Together", and work hand in hand to create even greater achievements.

Plastic steel bending is a vital process in modern construction and industrial applications, allowing the creation of aesthetically pleasing, durable, and functional profiles.

For architects, engineers, and construction teams, partnering with a professional high-precision C-channel bending service is essential to successfully bring innovative designs to life while maintaini

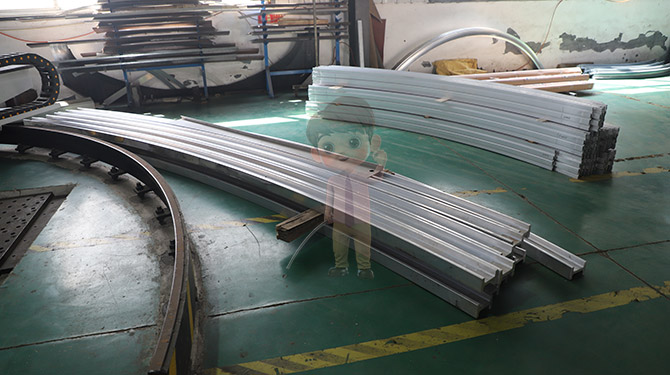

Advanced aluminum profile bending techniques provideprecision solutions for complex curved structures, enabling modern industries to meet increasingly demanding design and structural requirements.

By combining thoughtful equipment selection with proactive maintenance practices, manufacturers can achieve sustainable, high-efficiency aluminum bending operations that meet the rigorous demands of t