High-Accuracy Curve Forming: Achieving Consistent Bends in Aluminum, Steel, and Alloy Materials

In modern manufacturing and construction, precise bending and curve forming of metals is critical for creating durable, aesthetically appealing, and structurally sound components. From architectural facades and automotive frames to aerospace assemblies and industrial machinery, achieving consistent bends in materials like aluminum, steel, and various alloys is essential to meet both functional and design specifications. High-accuracy curve forming, therefore, has become a cornerstone of advanced fabrication, ensuring that components not only fit perfectly within assemblies but also maintain their mechanical integrity over time.

1. The Importance of High-Accuracy Bending

Metal bending might seem simple at first glance—applying force to a metal piece to form a curve—but in reality, it involves complex considerations of material properties, geometry, and process control. High-accuracy bending is critical for several reasons:

1.1 Structural Integrity

Inconsistent bends can lead to stress concentrations, weak points, or unintended deformations. For applications such as automotive chassis, aerospace components, or load-bearing architectural elements, even minor deviations can compromise structural integrity, potentially resulting in failure under load. Accurate curve forming ensures that the metal maintains its designed stress distribution, maximizing strength and durability.

1.2 Assembly Precision

Components often must fit precisely with other parts in an assembly. A slight deviation in bend radius or angle can cause misalignment, making assembly difficult or even impossible. High-accuracy curve forming guarantees consistent geometries, which simplifies assembly, reduces scrap, and improves overall production efficiency.

1.3 Aesthetic Quality

For visible applications, such as aluminum panels for building facades or decorative structures, uniform curves are essential for visual appeal. Uneven bends or warping can compromise the overall appearance and reduce the perceived quality of the finished product.

2. Material Considerations in Curve Forming

Different metals respond differently to bending processes. Understanding these properties is crucial to achieving consistent results.

2.1 Aluminum

Aluminum is lightweight and highly ductile, making it easier to bend than steel. However, it has a tendency to spring back slightly after bending, which must be accounted for in high-precision processes. Its low modulus of elasticity means the material can deform under stress if not properly supported during forming.

2.2 Steel

Steel is stronger and stiffer than aluminum, requiring higher forces for bending. High-carbon steels, in particular, can crack if over-stressed, while low-carbon steels are more forgiving. Accurate curve forming in steel requires precise control of bending force, speed, and tooling design to prevent material failure.

2.3 Alloy Materials

Specialized alloys, including stainless steel, titanium, and nickel alloys, often have unique properties such as higher strength-to-weight ratios or corrosion resistance. These materials may require specialized bending techniques, controlled heating, or multi-step forming processes to achieve the desired curvature without compromising structural performance.

3. Techniques for High-Accuracy Curve Forming

Achieving precise and repeatable bends requires advanced forming techniques and modern equipment. Several widely used methods include:

3.1 Roll Bending

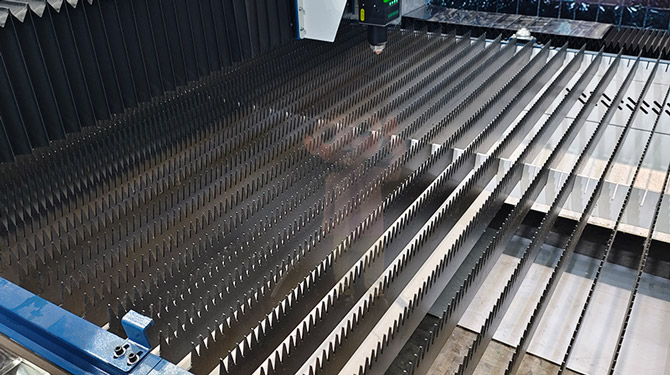

Roll bending uses a series of rollers to gradually form the metal into a curve. This technique is ideal for long, continuous curves and large-radius bends. Precision is achieved through careful calibration of roller positions, pressure, and feed speed.

3.2 Press Brake Forming

Press brakes apply force through a die to bend metal sheets at specific angles. CNC-controlled press brakes allow for high repeatability and accuracy, making them suitable for complex, multi-step bends in both sheet metal and plate materials.

3.3 Mandrel and Rotary Draw Bending

Mandrel bending supports the interior of hollow tubes, preventing collapse or wrinkling during the bend. Rotary draw bending is particularly effective for creating tight-radius curves in tubular aluminum, steel, and alloy components, delivering precise bend angles and consistent curvature.

3.4 Heat-Assisted Bending

For high-strength or hard alloys, applying controlled heat can reduce material stress and improve bend accuracy. Heating softens the metal locally, allowing it to form without cracking or distortion, and is often combined with other mechanical bending techniques.

4. Quality Control and Consistency

High-accuracy curve forming is not only about the process itself but also about monitoring and maintaining consistency. Modern fabrication facilities use several measures to ensure quality:

*Laser or Optical Measurement Systems: Measure bend angles, radii, and surface geometry in real time.

*CNC Programming: Automated bending ensures that each component matches the exact specifications.

*Material Testing: Checking hardness, tensile strength, and elasticity helps predict behavior during bending.

*Process Simulation: Software can simulate the bend process, predicting springback, deformation, or stress concentrations before production begins.

By integrating these quality control methods, manufacturers minimize scrap, reduce rework, and ensure that components meet stringent tolerances.

5. Applications of High-Accuracy Curve Forming

Precise bending is essential across multiple industries:

5.1 Architectural and Construction

Curved aluminum panels, steel structural elements, and decorative alloy components require consistent bends for both aesthetic and structural purposes. High-accuracy bending ensures seamless installations and visually appealing results.

5.2 Automotive Industry

Chassis frames, exhaust systems, and structural supports often include bent steel or aluminum tubes. Precision forming ensures vehicle safety, structural integrity, and proper alignment of mechanical components.

5.3 Aerospace and Aviation

Aircraft fuselages, wing structures, and support frames require extreme precision. High-accuracy curve forming is critical to maintain aerodynamic performance and ensure compliance with strict safety standards.

5.4 Industrial Machinery and Equipment

Pipes, conduits, and machine frames need consistent bends to fit complex machinery layouts. Accurate bending reduces assembly time and improves overall operational efficiency.

6. Advantages of High-Accuracy Curve Forming

*Consistency: Produces identical components for large-scale production.

*Reduced Material Waste: Minimizes scrap caused by misbends or deformation.

*Enhanced Structural Performance: Maintains integrity and load-bearing capacity.

*Improved Aesthetics: Smooth, uniform curves enhance visual quality.

*Process Efficiency: Reduces time and labor compared to manual or trial-and-error bending.

High-accuracy curve forming is a critical capability for modern manufacturing, enabling consistent, precise bends in aluminum, steel, and alloy materials. By understanding material behavior, employing advanced bending techniques, and integrating robust quality control measures, manufacturers can deliver components that meet both structural and aesthetic requirements. From architecture and automotive engineering to aerospace and industrial machinery, precise bending ensures performance, reliability, and efficiency, making it an indispensable part of today’s advanced fabrication processes.

For companies seeking precision, consistency, and scalability in curved metal components, investing in high-accuracy bending technology is no longer optional—it is a foundational requirement for competitive advantage in modern manufacturing.

27

2025-11

Number of visitors:1

HOT NEWS

-

Choosing the Right Metal Bending Technique for Your Production Needs

2026-02-26

-

Precision Hot Bending Solutions for Custom Metal Profiles

2026-02-13

-

Concentric frequency with growth: Sheng Dara bend to build a shared happiness

2026-02-04

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST