Exploring the Techniques and Tools for Bending Aluminum Rods: A Comprehensive Guide

Bending aluminum rods is a fundamental skill in various industries, including construction, manufacturing, and artistic applications. Whether you're a DIY enthusiast, an engineer, or an artist, understanding the techniques and tools involved in bending aluminum can enhance your projects and improve the quality of your work. This comprehensive guide will explore the methods, tools, and best practices for bending aluminum rods effectively.

Before diving into bending techniques, it’s essential to understand the properties of aluminum. Aluminum is a lightweight, corrosion-resistant metal known for its malleability and ductility. These properties make it an excellent choice for bending; however, they also require careful consideration of the bending methods to avoid cracking or warping. The most commonly used alloys for bending are 6061 and 6063, which offer a good balance of strength and flexibility.

Techniques for Bending Aluminum Rods

1.Cold Bending

Cold bending involves shaping the aluminum rod without applying heat. This method is widely used for thin-walled rods and smaller diameters. It can be done manually or with the help of bending tools.

-Manual Bending: For small projects, you can use your hands or simple tools like pliers. Ensure to apply gradual pressure to avoid kinks.

-Using a Hand Bender: Hand benders come in various sizes and shapes, allowing for precise bends. They typically have a groove for the rod and a lever to apply pressure.

2.Hot Bending

Hot bending is used for thicker rods or when tighter bends are required. This method involves heating the aluminum to its bending temperature (approximately 300°F to 400°F) to increase malleability.

-Heat Source: A propane torch or an oven can be used to heat the aluminum. Always use heat-resistant gloves and eye protection when working with heated materials.

-Bending Process: Once the aluminum reaches the desired temperature, it can be bent using a bending jig or by hand. The heat makes the material more pliable, reducing the risk of cracking.

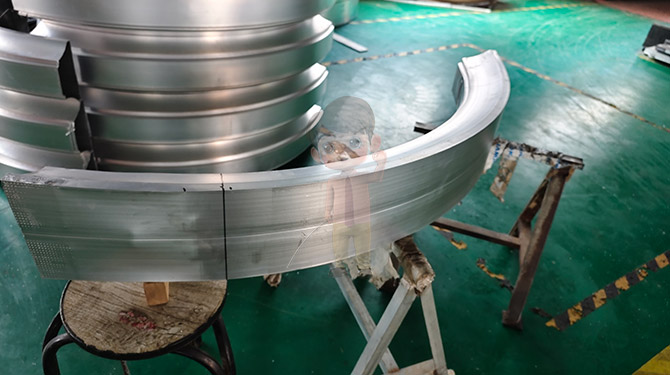

3.Using Bending Jigs and Fixtures

Bending jigs and fixtures are custom-made tools designed to hold the aluminum in place while bending. They ensure consistent and accurate bends, especially for repeated tasks.

-DIY Jigs: You can create a simple jig using wood or metal to guide the aluminum rod during the bending process.

-Commercial Jigs: Many manufacturers offer jigs specifically designed for bending aluminum rods, which can help achieve precise angles and shapes.

To effectively bend aluminum rods, you’ll need a variety of tools. Here are some essentials:

1.Bending Tools

-Hand Bender: A versatile tool for manual bending.

-Pipe Bender: Ideal for larger diameter rods, offering more leverage.

2.Heat Source

-Propane Torch: Useful for heating specific areas of a rod for hot bending.

-Oven: Suitable for heating larger sections of aluminum.

3.Protective Gear

-Gloves: Heat-resistant gloves to protect your hands during hot bending.

-Safety Goggles: To protect your eyes from flying debris or hot metal.

4.Measuring and Marking Tools

-Calipers: For precise measurements of diameter and bend angles.

-Marker: A permanent marker or scribe for marking the rod before bending.

Best Practices for Bending Aluminum Rods

1.Plan Your Bend: Before starting, sketch out your design and mark where the bends will occur. This helps avoid mistakes and ensures accuracy.

2.Use the Right Aluminum Alloy: Different alloys have different bending capabilities. Choose an alloy that suits your project requirements.

3.Gradual Pressure: Apply pressure slowly and evenly to prevent cracking. If you encounter resistance, stop and reassess.

4.Cooling and Finishing: After bending, allow the aluminum to cool naturally. If necessary, you can use a file or sandpaper to smooth out any rough edges.

5.Practice: If you’re new to bending aluminum, practice on scrap pieces to refine your technique before working on your final project.

Bending aluminum rods can be a rewarding and practical skill, whether for professional applications or personal projects. By understanding the properties of aluminum, utilizing the right techniques and tools, and following best practices, you can achieve accurate and aesthetically pleasing results. With practice and experimentation, you’ll be able to master the art of bending aluminum and create stunning designs that showcase your craftsmanship. Whether you're building a custom frame, creating artistic sculptures, or crafting functional components, the possibilities are endless with the right knowledge and tools at your disposal.

19

2025-06

Number of visitors:1

HOT NEWS

-

Concentric frequency with growth: Sheng Dara bend to build a shared happiness

2026-02-04

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

-

Advanced Aluminum Profile Bending Techniques: Precision Solutions for Complex Curved Structures

2026-01-06

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST