Bending Aluminum Tubing: Common Mistakes to Avoid and Tips for Success

Bending aluminum tubing is a popular process in various industries, from automotive to aerospace, due to aluminum's lightweight yet strong properties. However, achieving a perfect bend can be challenging, and several common mistakes can lead to structural weaknesses or aesthetic flaws. In this article, we will explore these pitfalls and provide essential tips to ensure your bending projects are successful.

Common Mistakes to Avoid

1.Choosing the Wrong Type of Aluminum Alloy

Not all aluminum alloys bend the same way. Some are more malleable than others, which affects how they respond to bending. For instance, 6061 aluminum is a popular choice due to its excellent machinability and weldability, but if you use a more brittle alloy, you might encounter cracking during the bending process. Always familiarize yourself with the specific characteristics of the aluminum alloy you are using.

2.Inadequate Preparation

Before bending, it's crucial to prepare the aluminum tubing properly. This includes cleaning the surface to remove any dirt or oxidation and ensuring the ends are cut squarely. If the tubing is not prepared adequately, it can lead to uneven bends or damage during the bending process.

3.Using Improper Tools or Equipment

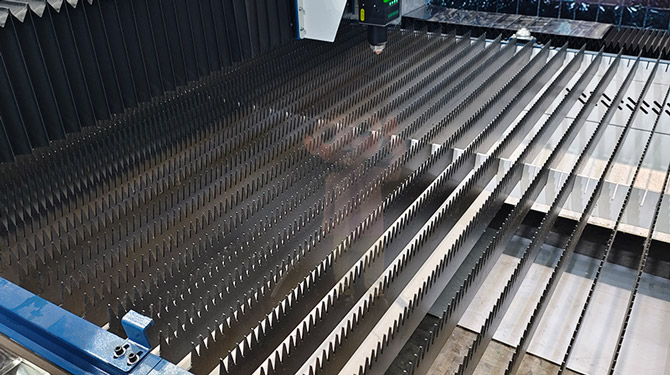

Utilizing the wrong tools can result in poor bends and increased risk of damage. Whether you are using a manual bender or a CNC machine, ensure that the equipment is suitable for the diameter and thickness of the tubing you are working with. Additionally, using worn-out or incorrect dies can lead to distortion and inaccuracies.

4.Neglecting the Bend Radius

The bend radius is critical in aluminum bending. A radius that is too tight can cause the aluminum to kink or crack, while a radius that is too large can result in a less aesthetically pleasing bend. Always refer to guidelines or manufacturer specifications to determine the appropriate bend radius for your specific tubing.

5.Ignoring the Effects of Heat

Aluminum has a relatively low melting point, and excessive heat during the bending process can lead to warping or structural weakness. While some bending techniques may require heat to aid in the process, it’s essential to control the temperature carefully. Too much heat can alter the alloy properties, leading to failure down the line.

6.Overlooking Post-Bending Treatment

After bending, the aluminum may require additional treatments, like annealing or surface finishing, to enhance its properties and appearance. Failing to do this can lead to corrosion or reduced strength in the final product. Consider applying protective coatings or treatments to extend the life of the aluminum tubing.

Tips for Success

1.Select the Right Alloy

Choose an aluminum alloy that is known for its bending capabilities. Alloys such as 6061 and 3003 are commonly used due to their favorable properties. Research and consult with material suppliers to find the best alloy for your specific application.

2.Use the Correct Tools and Dies

Invest in high-quality bending tools designed for aluminum tubing. Ensure that the dies match the specifications of the tubing's diameter and wall thickness. Properly calibrated machines will provide consistent results with minimal risk of defects.

3.Create a Bending Plan

Before starting the bending process, outline a detailed plan that includes measurements, bend angles, and desired outcomes. This plan will serve as a roadmap, ensuring you stay on track and avoid unnecessary mistakes.

4.Practice on Scrap Material

If you're new to bending aluminum tubing, practice on scrap pieces before working on your final product. This will help you get a feel for the process, allowing you to make adjustments and avoid mistakes when it counts.

5.Monitor Bend Progress

During the bending process, continually check the progress to ensure that the angle and shape meet your specifications. Stopping periodically to assess the bend can help you make adjustments before any irreversible damage occurs.

6.Consider Professional Assistance

If you are working on a complex project or are unsure about your bending skills, consider seeking help from professionals. Experienced fabricators can provide valuable insights and perform high-quality bends that meet industry standards.

Bending aluminum tubing can be a highly rewarding process when done correctly. By understanding the common mistakes to avoid and implementing the tips provided, you can enhance your bending technique and achieve successful results. Whether for a DIY project or professional application, careful planning and execution are key to maximizing the benefits of aluminum tubing. With practice and the right knowledge, you can master the art of bending aluminum tubing and create structures that are both functional and aesthetically pleasing.

18

2025-06

Number of visitors:1

HOT NEWS

-

Concentric frequency with growth: Sheng Dara bend to build a shared happiness

2026-02-04

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

-

Advanced Aluminum Profile Bending Techniques: Precision Solutions for Complex Curved Structures

2026-01-06

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST