Mastering the Art of Bending Aluminum Profile Decorative Lines: Techniques and Applications

Aluminum has become a favored material in various industries due to its lightweight, strength, and versatility. Among its many applications, the bending of aluminum profiles for decorative purposes has gained significant attention, particularly in architecture, interior design, and product manufacturing. This article delves into the techniques and applications of bending aluminum profile decorative lines, providing insights into the craftsmanship and innovation behind this art form.

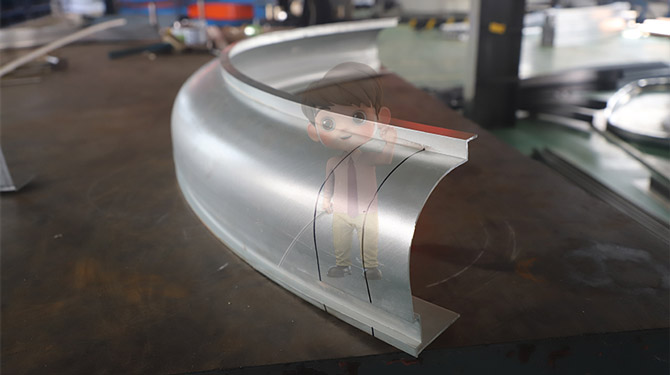

Aluminum profiles are extruded shapes that are fabricated from aluminum alloy. They come in various forms, including bars, tubes, and sheets, and can be designed to meet specific structural or aesthetic requirements. Bending aluminum profiles involves creating curves or angles in these profiles without compromising their integrity or appearance. This process is crucial for achieving the desired visual impact in design projects.

Techniques for Bending Aluminum Profiles

1.Heat Bending

Heat bending involves applying heat to the aluminum profile to make it malleable. This technique is particularly effective for achieving sharp angles or curves. The process typically includes the following steps:

-Preparation: Clean the aluminum surface to remove any contaminants.

-Heating: Use a heat gun or oven to evenly heat the aluminum to its bending temperature, which varies depending on the alloy (usually between 300°F to 700°F or 150°C to 370°C).

-Bending: Once the aluminum is heated, it is carefully bent into the desired shape using jigs or molds to ensure accuracy.

-Cooling: Allow the aluminum to cool naturally to retain its new shape.

2.Cold Bending

Cold bending is performed at room temperature and is suitable for creating gentle curves. This method is less labor-intensive and requires special tools:

-Bending Machines: Use a hydraulic or manual bending machine, which applies pressure to the aluminum profile in a controlled manner, allowing for precise bends.

-Roll Bending: For larger profiles, roll bending machines can create uniform curves by passing the profile through a series of rollers that gradually shape it.

3.Die Bending

Die bending involves using a custom-made die to shape the aluminum profile. This technique is ideal for high-volume production and ensures consistency across multiple pieces:

-Designing the Die: A die is designed based on the desired bend, which can accommodate various angles and curves.

-Pressing the Aluminum: The aluminum profile is placed in the die and subjected to significant pressure, which forces it into the desired shape.

4.CNC Bending

Computer Numerical Control (CNC) bending represents a cutting-edge approach to bending aluminum profiles. This method utilizes computer software to control the bending process, ensuring precision and repeatability:

-Programming: The desired bend specifications are programmed into the CNC machine.

-Execution: The machine automatically bends the aluminum profile according to the specified parameters, which is particularly beneficial for complex designs.

Applications of Bending Aluminum Profiles

1.Architectural Elements

Bending aluminum profiles is frequently employed in architectural applications, such as creating decorative facades, canopies, and signage. The ability to bend aluminum allows architects to design unique structures that capture the imagination and enhance aesthetic appeal.

2.Interior Design

In interior design, bent aluminum profiles can be used for lighting fixtures, furniture, and decorative wall panels. The sleek, modern look of bent aluminum complements contemporary design trends, and its versatility allows it to be integrated into various styles.

3.Automotive Industry

The automotive industry utilizes bent aluminum profiles for both structural and aesthetic purposes. Components such as frames, trim, and decorative elements benefit from the lightweight and corrosion-resistant properties of aluminum, contributing to overall vehicle efficiency and appearance.

4.Consumer Products

Many consumer products, from electronics to home appliances, incorporate bent aluminum profiles for both functionality and design. The lightweight nature of aluminum makes it an ideal choice for portable products, while its aesthetic appeal enhances the overall look.

Mastering the art of bending aluminum profile decorative lines involves a combination of technique, creativity, and precision. Whether through heat bending, cold bending, die bending, or CNC bending, each method offers unique advantages that cater to different applications. As industries continue to embrace aluminum for its versatility and aesthetic potential, the demand for innovative bending techniques will only grow, pushing the boundaries of design and functionality. By understanding these techniques and their applications, designers and manufacturers can unlock new possibilities in their projects, creating striking and sustainable solutions for the future.

23

2025-09

Number of visitors:1

HOT NEWS

-

Concentric frequency with growth: Sheng Dara bend to build a shared happiness

2026-02-04

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

-

Advanced Aluminum Profile Bending Techniques: Precision Solutions for Complex Curved Structures

2026-01-06

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST