Aluminum Bending in Construction: How It Shapes Structural Integrity and Design

Aluminum bending is a pivotal process in the construction industry, playing a crucial role in shaping both the structural integrity and aesthetic design of various projects. As one of the most versatile materials available, aluminum offers a unique combination of strength, lightweight properties, and resistance to corrosion, making it an ideal choice for a wide range of applications in construction. In this article, we will explore the significance of aluminum bending, the techniques used, and its impact on modern architectural design and structural performance.

Aluminum's lightweight nature, coupled with its high strength-to-weight ratio, allows for innovative design possibilities that would be challenging with traditional materials like steel or concrete. This quality is particularly valuable in construction, where reducing weight can lead to savings in both material costs and structural support requirements. Additionally, aluminum’s resistance to corrosion ensures longevity and reduces maintenance costs, making it a sustainable choice for both residential and commercial buildings.

Aluminum bending involves various techniques, each suited to specific applications and design requirements:

1.Cold Bending: This method involves bending aluminum at room temperature, which helps maintain the material's original properties. Cold bending is commonly used for thin-walled sections and allows for precise angles and curves without compromising structural integrity.

2.Hot Bending: In this technique, aluminum is heated before bending, making it more malleable. This approach is often employed for thicker sections or complex shapes, as it reduces the risk of cracking or breaking during the bending process.

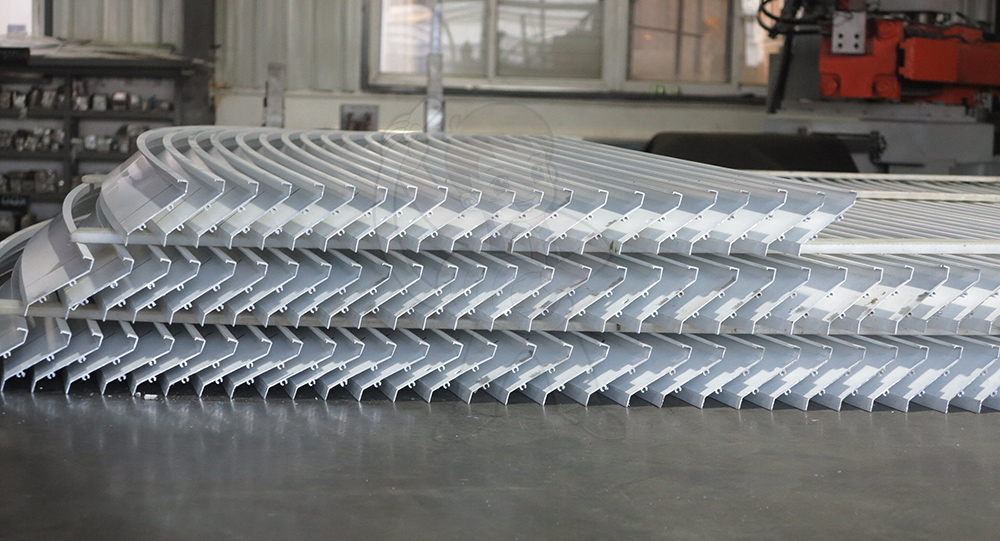

3.Roll Bending: Used for creating large curves or arcs, roll bending involves passing aluminum sheets through a series of rollers. This technique is beneficial for constructing curved beams or panels, enhancing both functionality and aesthetic appeal.

4.Press Brake Bending: A common method for producing precise bends at specific angles, press brake bending uses a machine to apply force to the aluminum sheet, creating accurate folds. This technique is particularly useful for producing components that require exact specifications.

The bending process significantly influences the structural integrity of aluminum components. Proper bending techniques ensure that the material retains its strength and durability, which is essential for load-bearing elements such as beams, columns, and frames. The ability to shape aluminum into complex forms without compromising its structural capabilities allows architects and engineers to push the boundaries of design while ensuring safety and stability.

For instance, in high-rise buildings, aluminum bending is often utilized to create lightweight, yet strong, framework systems that can withstand harsh environmental conditions. The flexibility of aluminum also allows for the incorporation of dynamic design elements, such as curved facades or cantilevered structures, which can enhance both functionality and visual appeal.

Beyond its structural benefits, aluminum bending also plays a significant role in architectural aesthetics. The versatility of aluminum allows designers to create intricate shapes and forms that can elevate the overall appearance of a building. Whether it’s a sleek, modern facade or a more traditional design incorporating arches and curves, aluminum bending provides the flexibility needed to achieve a wide range of architectural styles.

Moreover, aluminum can be easily finished with various coatings, colors, and textures, further enhancing its visual appeal. This adaptability makes aluminum a popular choice for contemporary architecture, where creativity and innovation are paramount.

As the construction industry increasingly focuses on sustainability, aluminum's recyclability and energy efficiency become even more critical. The bending process itself can be optimized to reduce waste and energy consumption, aligning with global efforts to minimize the environmental impact of construction activities.

Future trends in aluminum bending may include advancements in automated bending technologies, which can enhance precision and reduce labor costs. Additionally, the integration of smart materials and technologies could lead to new applications in building design and construction, allowing for even greater efficiency and sustainability.

Aluminum bending is an essential process that shapes both the structural integrity and design of modern construction projects. Its lightweight nature, strength, and flexibility enable architects and engineers to explore innovative designs while ensuring safety and durability. As the industry continues to evolve, the role of aluminum bending will undoubtedly expand, paving the way for more sustainable and aesthetically pleasing construction solutions. Whether in residential buildings, commercial spaces, or infrastructure projects, aluminum will remain a key player in the future of construction.

28

2025-07

Number of visitors:1

HOT NEWS

-

Concentric frequency with growth: Sheng Dara bend to build a shared happiness

2026-02-04

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

-

Advanced Aluminum Profile Bending Techniques: Precision Solutions for Complex Curved Structures

2026-01-06

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST