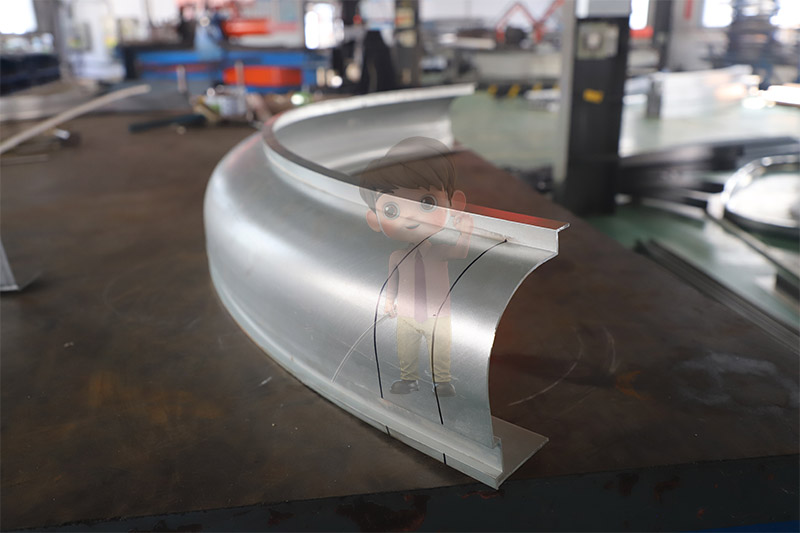

Bending of aluminum profile decorative lines

Aluminum profile decorative lines (such as wall lines, ceiling borders, and furniture decorative strips) are often required to be bent into arcs or complex curves due to their aesthetic appeal.

Stretch Bending:

- Principle: Bend the aluminum profile to the shape of the mold under tension, combining tensile force and bending force to reduce springback.

- Applicable scenarios: Suitable for small and medium radii and complex curves (such as S-shaped and wavy decorative lines).

- Advantages: Reduce internal stress in the material, suitable for high-precision requirements.

- Tools: Stretch bending machine, roll bending machine, pipe bending machine, and custom molds.

- Case: Shanghai Zhonghai City.

When aluminum profiles are bent, complex stresses and deformations occur, which can affect the quality of decorative lines. The following are the key solutions for bending aluminum profiles by Shengda:

Normal stress distribution:

- During bending, the outer side is under tensile stress, the inner side is under compressive stress, and the stress at the neutral axis is zero.

- Normal stress formula: \(\sigma=\frac{M\cdot y}{I}\), where \(M\) is the bending moment, \(y\) is the distance from the neutral axis, and \(I\) is the moment of inertia of the cross-section.

- Decorative lines are often thin-walled profiles (such as T-shaped or L-shaped), and the moment of inertia of the cross-section needs to be calculated to determine the maximum stress.

Strain and curvature:

- Strain \(\varepsilon=\frac{y}{R}\), where \(R\) is the bending radius.

- Aluminum profiles (such as 6063-T5) have good ductility, but small radius bending may cause plastic deformation or cracking.

Springback:

- Aluminum profiles have a high elastic modulus and are prone to springback after bending, affecting the accuracy of the arc.

- Solution: Use the tension-bending process to apply a pre-stretching force, or compensate for the springback amount in the mold design (usually 2-5%).

Common problems and solutions in the decorative bending processing of aluminum profiles:

Surface scratches or deformation:

- Cause: Rough surface of the rollers or molds, resulting in high friction during processing.

- Solution: Use polished molds or add lubricants (such as lubricating oil, film protection).

- Prevention: Select aluminum profiles with anodized or sprayed surfaces to increase wear resistance.

Cracking or breaking:

- Cause: The bending radius is too small, exceeding the material's ductility limit, or there are internal defects in the material.

- Solution: Choose aluminum alloys with good ductility (such as 6063, 6061), and control the minimum bending radius (generally 3-5 times the material thickness).

- Prevention: Heat treatment (such as T5/T6 state) to improve material toughness, and preheat if necessary.

Cross-sectional distortion:

- Cause: Uneven force distribution during bending for non-symmetric cross-sections (such as L-shaped, U-shaped).

- Solution: Use support fixtures to fix the cross-section or use CNC tension bending machines to control force distribution.

- Prevention: Design symmetrical cross-sections or simulate stress distribution before processing.

Insufficient dimensional accuracy:

- Cause: Springback, mold errors, or inaccurate equipment.

- Solution: Precisely control the bending angle through CNC equipment and use high-precision molds.

- Prevention: Conduct test piece tests before processing and adjust parameters.

Beijing Shengda Weiye Extruded Profile Bending Factory Tips for Attention

- Material Selection: Choose the appropriate aluminum alloy profile and surface treatment method based on decoration requirements, taking into account both aesthetics and durability.

- Minimum Bending Radius: Refer to the thickness of the aluminum profile and the type of alloy to avoid cracking due to too small a radius.

- Equipment Precision: Prioritize CNC roll bending machines or drawing machines to reduce human error.

- Environmental Factors: Avoid dampness during processing and storage to prevent oxidation or deformation of the aluminum profiles.

If you have more specific requirements (such as a certain cross-sectional shape, specific arc, equipment recommendation, or suggestions for a specific area such as Shengda Bending Factory), please contact us!

Leave us a message

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST