Numerical simulation and process parameter optimization of profile stretch bending in Beijing Stretch Bending Factory

With the rapid development of aerospace, automobile, high-speed train and other industries, the trend of large size and integration of parts is obvious. The use of large profile parts is increasing day by day, and one of the main manufacturing processes, tensile bending forming, has attracted more and more attention. The section shape type of the profile is many, the difference is large, the different shape and bending size of the profile in the process of stretching bending problems are not the same, in addition to the existence of wrinkling, cracking and rebound and plate forming the same defects, but also there are special problems such as section distortion and longitudinal distortion, quality control difficulty.

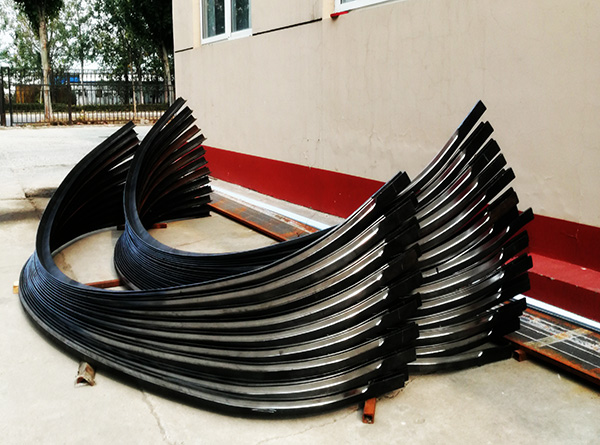

In the process of tensile bending, because of its hollow, thin wall, asymmetry and other characteristics, it is easy to appear cross-section distortion, outer edge rupture, unloading springback and torsion after springback, forming accuracy is difficult to ensure. Finite element numerical simulation is a kind of forming process optimization technology, which has been widely used in production practice. It can effectively shorten the production cycle, reduce the production cost of trial and error method, and improve the machining accuracy. The numerical simulation and process parameter optimization of Beijing stretch bending Factory are used to analyze the process of stretch bending of profiles, which can optimize the process parameters such as loading mode and loading speed, reduce and prevent the defects such as cross-section distortion, and provide a reliable basis for the formulation of forming process specifications in actual production.

In view of the problems in the forming of large size open profile parts used in aerospace industry, a suitable die was designed, and with the help of the forming method of filling material, the stretching and bending process was numerically simulated by software and the technological parameters were optimized, which effectively reduced the cross-section distortion. According to the numerical simulation results, a reasonable loading forming method was proposed, which provided guidance for the production practice.

Tensile bending of profiles means that tangential tension is applied when the profiles are bent, so as to overcome the inner wrinkle and the stress distribution in the sending section, so as to reduce springback and improve the forming accuracy. Tensile bending can be divided into force - controlled and displacement - controlled tensile bending. From the point of view of the equipment used, the tension bending forming controlled by the force can be divided into three ways: straight into the table tension bending forming, rotary arm tension bending forming and rotary table tension bending forming.

Pull-bend and pull-bend - pull loading modes are often used in actual production. The advantages of the pull-bending-pull-loading mode are that the initial deformation of the material can be eliminated, the residual stress is small, and the web can be effectively prevented from buckling. The disadvantage is that the process of reinforcement is affected by friction, the uneven force of the material causes uneven deformation, and increases the cross section distortion.

The pull-bending method can also eliminate the initial deformation of the material and effectively prevent buckling and wrinkling. At the same time, the operation is simpler and is not affected by friction. The disadvantage is that the amount of rebound is larger.

At present, the research of stretch bending mainly adopts three methods: analytical calculation method, experimental analysis method and numerical simulation. Because of the complexity of stretch bending forming of profiles, the theoretical analysis needs to make many assumptions and does not involve the change of section shape, so the theoretical analysis method has certain limitations and is not enough to guide the actual production. Experimental studies are expensive and take a long time. Using numerical simulation to simulate the process can shorten the production cycle, reduce the production cost of trial and error, and improve the accuracy of processing.

21

2023-04

Number of visitors:5589

HOT NEWS

-

Precision and Efficiency in Plastic Steel Bending: Key Techniques and Benefits

2026-01-26

-

High-Precision C-Channel Steel Bending Solutions for Customized Structural and Architectural Applications

2026-01-16

-

Advanced Aluminum Profile Bending Techniques: Precision Solutions for Complex Curved Structures

2026-01-06

-

Selection and Maintenance Strategies for Aluminum Bending Equipment

2025-12-27

English

English Chinese

Chinese Japan

Japan German

German

LIST

LIST