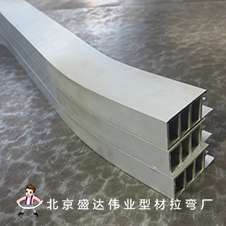

Metal tensile bending

Non industrial material bending

The stretching and bending forming of non industrial metal materials is a common processing technique. This process mainly involves plastic deformation of non industrial metal materials (such as aluminum, copper, magnesium alloys, etc.) along a certain curve or shape by applying external force.

During the bending process, the material is first heated to an appropriate temperature to improve its plasticity and ductility, thereby reducing cracks and other defects during deformation. Subsequently, using specialized bending equipment such as bending machines or molds, tension and bending forces are applied to gradually form the desired bending shape of the material.

The advantage of this process is that it can achieve complex geometric shapes while preserving the strength and toughness of the material to a certain extent. In addition, non industrial metal materials usually have good corrosion resistance and lightweight characteristics, making products formed by stretch bending more competitive in many applications and providing important support for the development of various industries.

Non industrial material bending applications

Elevator and other lifting systems bend pipesElevator, Stair climbing machine, stair elevator, Cable car, anti fall railing, Hanging basket elevator, High altitude zip line Waiting for processing and manufacturing.

Furniture and interior decoration1. Cabinets and furniture frames: Furniture frames and cabinet door panels are often manufactured using stretch bending boards to provide streamlined appearance and structural support.

2. Decorative metal products: Metal bending can be used to manufacture various decorative metal products, such as metal screens, porches, decorative chandelier metal poles, glass frames, etc.

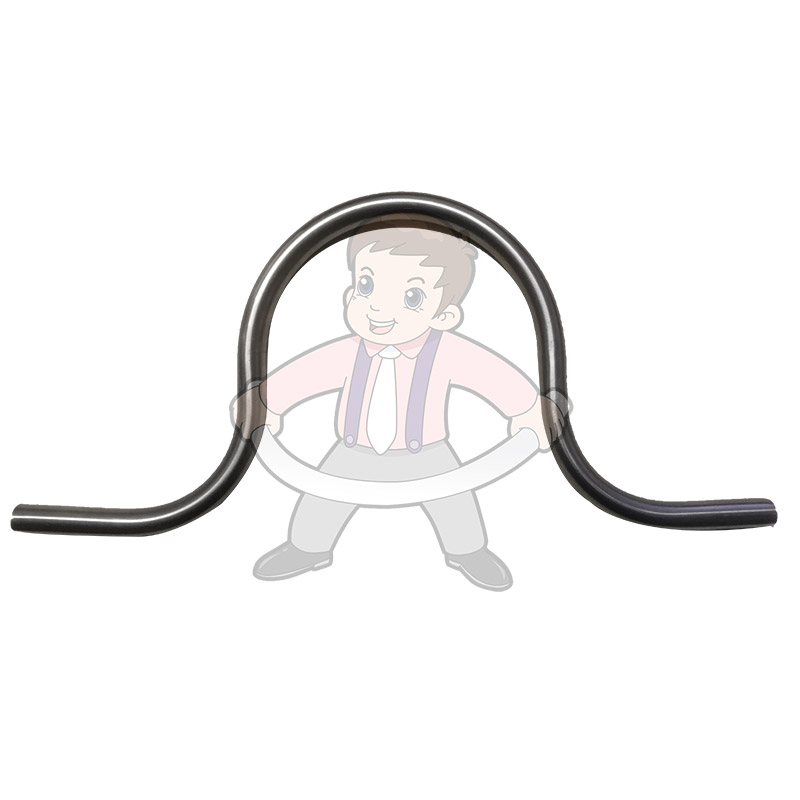

Fitness equipment bend pipe

English

English Chinese

Chinese Japan

Japan German

German